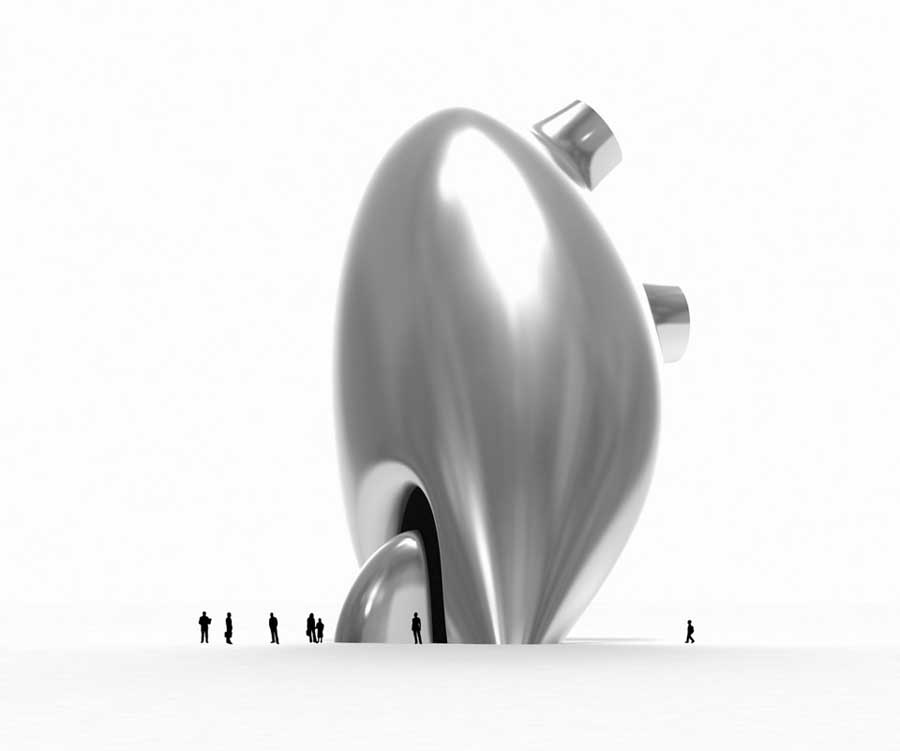

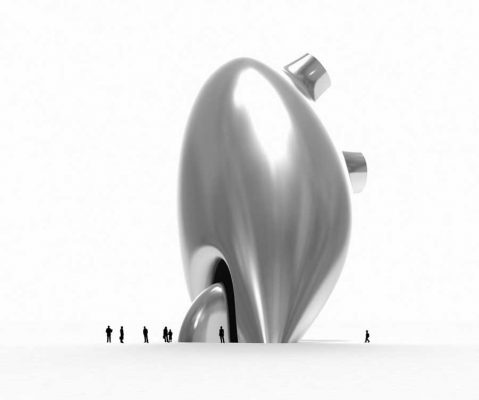

Formtexx Double-curvature surfaces, 3D Building Project, Photo, London Firm News, Design, Property Image

Formtexx UK : sheet metal development

Double-curvature surfaces, London Manufacturer, England, UK

1 Mar 2010

Manufacturing double-curvature surfaces

Formtexx

The late 1980s saw some radical developments in what became known as freeform, organic or zoomorphic architecture. Prior to this date most structures, with the exception of those in the craft and cultural tradition and the engineering work of the structural pioneers of the early 20th century, were constructed of planar elements in orthogonal arrangements set at regular intervals.

The ability to create double-curvature forms in a controllable manner was an essential requirement of this new building typology and was enabled by borrowing the emerging 3D software platforms being developed by the film animation, aerospace and automotive industries. Here in lies a problem that has dogged the architects ever since. Their buildings are one-off “prototypes” whereas the animation industry had never intended to bring their creations into the real world and the aerospace and the auto makers were intent on making many multiples with fixed tooling.

The problem for the construction industry arose when it came to transforming the creative digital data into coherent freeform buildings for which they had no obvious tools to produce large double-curvature surfaces, digitally. This state of affairs has persisted for twenty years with the R&D averse construction industry relying instead on a bewildering array of analogue traditional craft based fabricators and tangential industries, such as ship building, to provide one-off double-curvature constructions at monumental scales with an acceptable degree of accuracy.

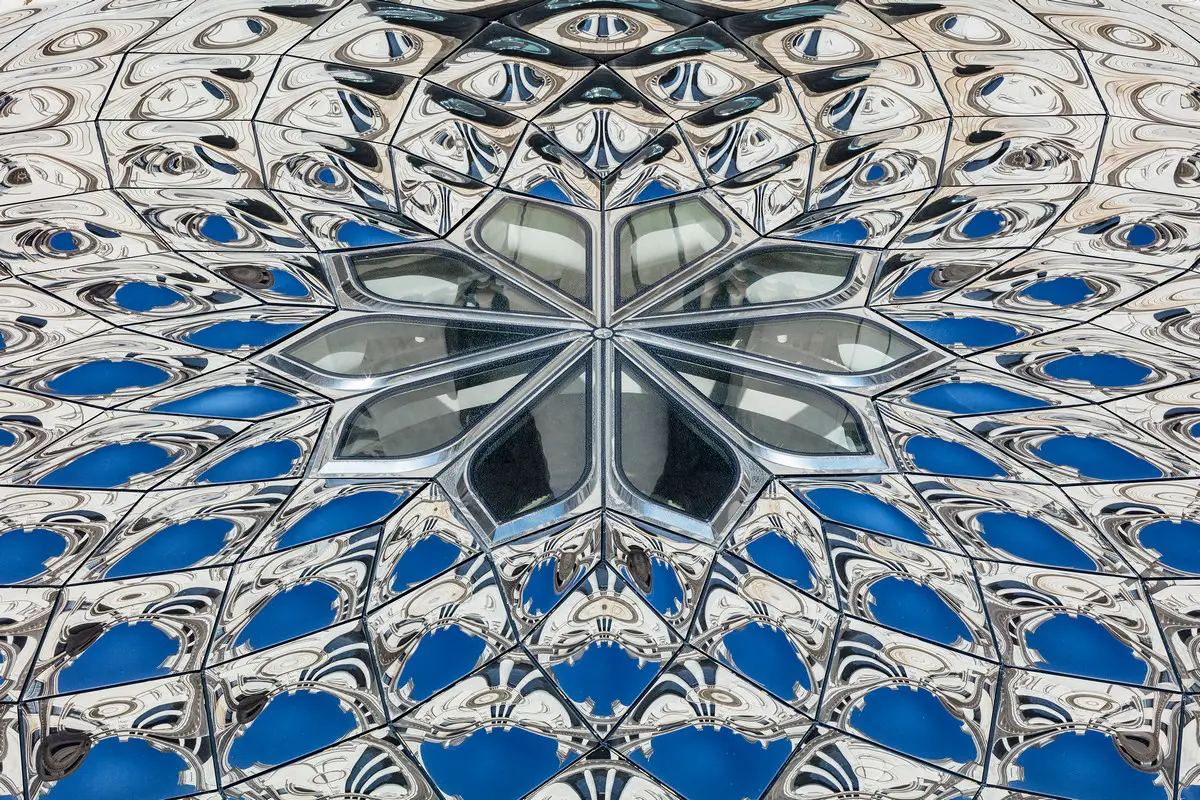

Traditionally sheet metal development falls into two categories, (i) manual analogue techniques of Wheeling, Rolling and Incremental sheet forming, producing unique shapes in small quantities with inherent dimensional deviation and (ii) die-stamping, producing identicle shapes in mass production quantities.

Formtexx anticipates an entirely new third category which combines the benefits of digital manufacture with non-repeating freeform geometry as standard: Formtexx is a CAD/CAM/CNC (patents applied) metal plate/sheet forming cell, producing custom 3D forms serially direct from CAD data in mass-production quantities with automotive quality.

Formtexx has closed the gap between digital design and digital manufacturing, in the facade sector.

Contact Formtexx:

John Gould, Formtexx, 5 Delancey Passage, Delancey Street, London NW1 7NN, UK

Contact details for this British company:

Phone: +44 (0)20 7387 7295 E-mail: [email protected]

Location: 5 Delancey Passage, Delancey Street, London NW1 7NN, England, United Kingdom

London Architectural Designs

London Architecture Designs – chronological list

London Architect – design practice listing on e-architect

London Architecture Designs – architectural selection below:

One Exchange Square, Broadgate, EC2

Design: Fletcher Priest Architects

image : Secchi Smith

One Exchange Square Broadgate Building

The Royal College of Art, Howie Street, SW11 4AY

Architects: Herzog & de Meuron

photo © Iwan Baan

Royal College of Art Battersea Campus

The OWO’S Grand Courtyard And Café La Pérouse Pavilion, Whitehall

Architect: DaeWha Kang Design

photo : Kyungsub Shin

The OWO Courtyard Pavilion, Raffles Whitehall

Architectural Products

Building Products – chronological list

Architectural Product Profiles – recent selection:

Oneiric Catamaran

Design: Zaha Hadid Architects

Oneiric catamaran

Oneiric Catamaran, Zaha Hadid Superyacht

Lignacite celebrates 75 years of manufacturing sustainable masonry for Britain

Lignacite celebrates 75 years of manufacturing masonry

Genesy lamp for Artemide : Zaha Hadid Architects

Kanera sink : GRAFT

Libeskind Villa : Daniel Libeskind

Ambar Light Fitting : Rogers Stirk Harbour + Partners

Comments / photos for the Formtexx Double-curvature Architecture page welcome