The Smile London Design Festival, Chelsea College of Arts Architecture, Architect, CLT Design Images

The Smile – London Design Festival

Tulipwood CLT Project: London Design Festival Landmark Project design by Alison Brooks Architects

27 Jul 2017

The Smile in London Shortlisted for the Wood Awards 2017

Twenty outstanding structures have been nominated for the Wood Awards 2017 shortlist, featuring some of Britain’s best architectural designs in wood. The judging panel, led by architect Michael Morrison of Purcell, visit all the shortlist projects in person, making this a uniquely rigorous competition. The shortlist will be showcased at the London Design Fair (Stand B05, Hall T2), Old Truman Brewery, 21st-24th September.

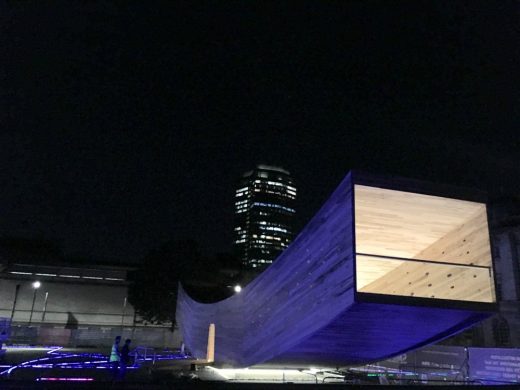

Conceived as a habitable arc, The Smile was a 3.5m high, 4.5m wide and 34m long curved timber tube that cantilevered 12m in two directions with viewing platforms at both ends. Up to 60 visitors could enter at one time through an opening where the arc touched the ground. Innovative solutions using long screws were developed, allowing the opening to be in the most highly stressed region.

The Smile was the first project in the world to use large hardwood CLT panels, the entire structure was made from just 12 tulipwood panels, each up to 14m long and 4.5m wide. The CLT panels were connected with 7,000 self-tapping screws. At the base, a glulam timber cradle filled with 20 tonnes of steel counterweights, allowed the project to be self-supporting. Perforations in the walls, concentrated in areas where there was less stress in the structure, brought dappled sunlight into the interior and dispersed where the timber was structurally working harder.

Location: Chelsea College of Arts, London

Architect: Alison Brooks Architects

Client: American Hardwood Export Council/London Design Festival

Structural Engineer: Arup

CLT Manufacturer: MERK Timber GmbH, Züblin Timber

Main Contractor/Joinery Company: Aldworth James & Bond

Lighting Designer: SEAM

Balustrade Joinery: John Stidworthy

Wood Supplier: Various

Wood Species: American Tulipwood

Wood Award Shortlisting for The Smile

21 + 20 Sep 2016

The Smile at London Design Festival

Design: Alison Brooks Architects

Location: Chelsea College of Arts, 16 John Islip Street, London SW1P 4JU, England, UK

The American Hardwood Export Council Presents The Smile by Architect Alison Brooks for The London Design Festival

THE AMERICAN HARDWOOD EXPORT COUNCIL PRESENTS

‘THE SMILE’ BY ARCHITECT ALISON BROOKS AND ARUP FOR

THE LONDON DESIGN FESTIVAL

The American Hardwood Export Council (AHEC) has collaborated with Alison Brooks Architects, Arup and the London Design Festival to present a cross-laminated tulipwood structure, ‘The Smile’ at the Chelsea College of Art Rootstein Hopkins Parade Ground from 17 September until 12 October.

The Smile is one of the Festival’s Landmark Projects, which can be inhabited and explored by the public. The spectacular, curved, tubular timber structure measures 3.5m high, 4.5m wide and 34m long and is effectively a beam curving up at both ends. Showcasing the structural and spatial potential of cross-laminated American tulipwood, Alison Brooks’ concept is the first ever ‘mega-tube’ made with construction-sized panels of hardwood CLT.

ABOUT CROSS LAMINATED TULIPWOOD

Cross-laminated timber (CLT) is an engineered timber that can be used to make the walls and floors of entire buildings. It has a layered construction with the wood fibres turned at right angles in each successive layer, creating a panel with equal strength in both directions, just like plywood. Weight for weight, CLT is stronger than concrete and it can also be machined to incredibly high tolerances. This makes it ideal for prefabrication and rapid assembly, reducing construction times by up to 30%.

CLT is usually made of a softwood called spruce, better known as the Christmas tree. Together with Arup, AHEC has started a process of experimenting with CLT made from fast-grown North American tulipwood. Testing has shown that the tulipwood is considerably stronger than spruce; it also has a superior appearance.

The Smile is the first project in the world to use large hardwood CLT panels, in fact the entire structure is made from just 12 huge tulipwood panels, each up to 14m long and 4.5m wide. Fabricating these panels in a real CLT production plant has been an important step forward, showcasing how the material can be used for commercial projects.

Q&A WITH ALISON BROOKS, ALISON BROOKS ARCHITECTS

Q: What are the aesthetic qualities of tulipwood CLT?

A: It’s a very interesting wood – it has wonderful grain and colour variation. Tulipwood also has a kind of sheen, so the grain is tight and smooth. Tulipwood can be selected to be clear and knot-free, offering a really clean-looking alternative to softwoods. I love the way the strips of wood in cross-laminated timber have a direction that expresses how the structure is working.

Q: How did the structural properties of tulipwood CLT inform your design for The Smile?

A:. I wanted to create something that uses tulipwood

CLT in its largest format possible, which is 4.5m x 20m plates, and to express the additional strength CLT can offer when it’s made of hardwood. The best way to express this strength was to combine these plates into a four-sided CLT hollow tube. This is a beam profile that works very well in tension and compression to achieve long spans. By making this CLT ‘tube’ into the shape of an arc at a huge scale, the plates form a dynamic, sensory space to inhabit. The result is a building that cantilevers from a single point in the centre. One of the most amazing qualities of the Smile is the thin-ness of the majority of its wall and floor panels – only 100mm thick. It’s an autonomous and self-supporting piece of architecture that touches the ground lightly.

Q: How did you make The Smile engaging and interactive?

A: The Smile’s form implies that it will rock. So the form itself is an invitation to test whether the pavilion moves, and how it feels to walk in on a curved floor. A single door and ramp from the square invites visitors to enter – something like our archetypal image of Noah’s Ark. Inside the door light spilling from the ends of the arc will invite you to walk up the slope of the curve to balconies at either end, rather like looking out from the rail of a ship.

The pavilion’s walls are perforated with oval holes, measuring between 12cm and 20cm. These allow daylight to filter in and track across the interior space throughout the day. The holes are placed in the parts of the CLT walls under the least amount of strain, a kind of structurally expressive ornament. After dark The Smile will emit beams of light from each end, elongating the structure. It has a playful quality – between a landscape structure and a building – and it creates sheltered spaces under its cantilevered arms.

Q&A WITH DAVID VENABLES, EUROPEAN DIRECTOR OF AHEC

Q: Softwood CLT is such a successful product, and one with a growing market. Why are you so keen to propose an alternative?

A: The bulk of the market is decided on cost, so using European softwood makes sense for structural framing. But in public buildings, or in housing, for instance, there are requirements for more specialised, higher-quality products. The greater strength or improved appearance of hardwood CLT will make it the material of choice, and quite possibly the only solution.

Q: Why commission an installation at the London Design Festival?

A: The Smile is not an installation at all, but something far more important – it’s effectively the latest stage in a 10- year project that challenges the way hardwood can be used structurally. Rather than doing our experimentation in a laboratory, we do it in public. It is risky, but the rewards are great.

Three years ago we worked with architects dRMM (de Rijke Marsh Morgan) and engineers at Arup to design The Endless Stair, the very first tulipwood CLT prototype, for the London Design Festival. As a result, debate about hardwood CLT spread across Europe and we learnt so much from the Endless Stair that we were able to take it to industrial production. The Smile will create further discussion and debate that widens opportunities. You will see how exciting and beautiful a building using CLT can be, and possibly consider it for a public space in London.

Q: How did you decide on your team for The Smile?

A: The team has been brilliant. These are serious companies giving up their time to follow through an idea because they believe in it. We’ve had a relationship with Alison for over 10 years. We first met doing lectures for architects in Germany, where she was talking about her pioneering use of timber for affordable housing. There’s a clever simplicity to her architecture, and a good bit of humility. Very quietly, she influences and changes thinking. She’s a strong advocate for timber in construction.

We could never have done this project without Arup; the idea to originally test the structural potential of tulipwood CLT (with the Endless Stair in 2013) came from our ongoing relationship with Arup. It is only in partnership that we were able to persuade ZÜBLIN Timber to trial the large industrial panels of tulipwood CLT used in The Smile. Their vast experience and expertise in the area of timber construction and particularly CLT has made it possible to meet the engineering challenge of The Smile, which may look simple in its form but is highly complex in terms of its timber engineering.

ZÜBLIN Timber, the manufacturer of the CLT for The Smile, has a reputation for specialist one-off projects, and the way that they make their CLT is different from the approach of other manufacturers. They use a vacuum press to create the multi-layer material rather than the pressurised plate approach that is most common. This allows them to create curved elements and to work with smaller quantities – both essential for The Smile.

Q: How sustainable is tulipwood CLT?

A: It’s good both for the American hardwood producers and for the environment. In order to use timber in the most environmentally friendly way, it is vital to use as much as possible of what is grown and harvested and to throw away as little as possible. There is a double win for tulipwood CLT. First the timber is abundant, naturally representing a large proportion of hardwood forests. And secondly, CLT uses the lowest grades of the timber – grades that are no longer exported for furniture production and so would otherwise have a very restricted market.

Q&A WITH ANDREW LAWRENCE, GLOBAL TIMBER SPCEIALIST ARUP

Q: Why are we seeing more and more timber being used for buildings?

A: Timber has many advantages, but I think the biggest is speed. Timber is lightweight and with computer fabrication it can now be machined to incredibly tight tolerances. This makes it ideal for prefabrication and rapid assembly. Assembling a timber building is like assembling a giant piece of flat pack furniture. The development of CLT has been a key part of the timber revolution as it gives us a way to create large timber panels which can be used for the walls and floors of entire buildings, without the need for any wet concrete trades.

Q: What makes The Smile such an important structure for timber?

A: The Smile is the most complex CLT structure that has ever been built. Not only does it have a double cantilever, but the entrance door is placed right at the centre where the stresses are highest. You’re effectively looking at two 15m cantilevers. If you turned the structure vertically and added the weight of 60 visitors at one end, it’s equivalent to the core stabilising a five-storey building. Nobody has ever built a core that slender in timber.

Q: What makes tulipwood so suitable for CLT?

A: Compared to other woods, tulipwood is surprisingly strong for its weight. It’s significantly stronger than spruce, but still low enough density to be easy to kiln dry, easy to machine, easy to transport and easy to screw into. Where improved strength and appearance are needed, I can see great potential for tulipwood CLT.

Q: What were the biggest engineering challenges of the project?

A: The structure is designed to resist about 10 tonnes of wind loading that tends to want to distort the rectangular cross section of the tube into a lozenge shape. The obvious solution would have been to install internal cross-bracing along the length of The Smile but this would have ruined Alison’s concept for a clean interior, so instead we’ve hidden timber beams above the roof enabling us to rigidly connect the walls to the roof to prevent the lozenging action.

We’ve also screwed The Smile down to a large wooden box, hidden under the ground and filled with 20 tonnes of steel weights. This is what stops The Smile tipping under the weight of people at one end, or overturning under a strong wind. The need for 20 tonnes of weights and for the 6,000 long screws that hold the CLT panels together, really gives a feel for the huge forces which The Smile has to resist.

www.thetulipwoodsmile.info

#thesmile

The Smile, London Design Festival – Background Information

ABOUT AHEC

For over 20 years the American Hardwood Export Council (AHEC) has been at the forefront of wood promotion in Europe, successfully building a distinctive and creative brand for U.S. hardwoods.

AHEC’s support for creative design projects such as The Wish List, Endless Stair, and now The Smile, for the London Design Festival demonstrate the performance potential of these sustainable materials and provide valuable inspiration.

AHEC pioneered the environmental impact assessment (EIA), an approach that has since been adopted by other industries. This measures a number of impacts: primary energy demand (from renewable and non-renewable resources); global warming potential; acidification potential; eutrophication potential; and, photochemical ozone creation potential.

www.americanhardwood.org

@ahec_europe

ABOUT ALISON BROOKS ARCHITECTS

Founded in 1996, Alison Brooks Architects has developed an international reputation for design excellence in projects ranging from urban regeneration and public buildings for the arts, to higher education and housing. ABA’s architecture is informed by their intensive research into the cultural, social and environmental contexts of each project. This approach enables the practice to develop authentic, responsive solutions for their buildings and urban schemes, each with a distinct identity.

Known for their sculptural approach to form and extraordinary attention to detail, Alison Brooks Architects is the only UK practice to have won the RIBA’s three most prestigious awards for architecture – the Stirling Prize, Manser Medal and Stephen Lawrence Prize. ABA’s numerous national and international awards include the 2012 Architect of the Year and Housing Architect of the Year.

ABA is designing major projects across the UK including the new Cohen Quadrangle at Oxford University, due to open in October 2016. ABA has recently received a RIBA Award for their work in the South Kilburn Estate, Ely Court. The practice will be exhibiting their research examining 20th century social housing and contemporary urban stewardship at the 2016 Venice Biennale.

www.alisonbrooksarchitects.com

@AlisonBrooksArc

ABOUT ARUP

With 13,000 engineers, designers and planners in 90 offices, Arup is the creative force behind many of the world’s most prominent projects in the built environment. The company has a multi-disciplinary team working with wood, including structural, fire, vibration, acoustic, building physics and façade engineers as well as material scientists that are leading experts in their fields. This has enabled Arup to develop many award-winning and innovative timber structures, helping to push the boundaries of the material.

www.arup.com

@ArupGroup

ABOUT ZÜBLIN TIMBER

ZÜBLIN Timber stands for ambitious and pioneered solutions in the field of timber construction. We are your single-source provider for the development, production, delivery, and execution of highquality construction systems, from timber construction projects to timber engineering to turnkey project execution. We, the timber construction team of Züblin, MERK and Stephan, work hand in hand with our clients to develop efficient solutions and a sustainable quality of life.

www.zueblin-timber.com

ABOUT THE LONDON DESIGN FESTIVAL

The London Design Festival is a key constituent of London’s autumn creative season, alongside London Fashion Week, Frieze Art Fair and the London Film Festival. Established in 2003 its role is to celebrate and promote London as the world’s design capital and gateway to the international design community and it has now established a reputation as one of the largest and most exciting design events in the world. This year the Festival will run from 17-25 September and over 400 events and installations will be on offer across the capital, from an exciting programme at the V&A to plus over 300 partners who will participate in the nine-day Festival.

www.londondesignfestival.com

@L_D_F

ABOUT UNIVERSITY OF THE ARTS LONDON

University of the Arts London (UAL) is Europe’s largest university for art, design, fashion, communication and the performing arts. It is a federation of six internationally renowned colleges: Camberwell College of Arts, Central Saint Martins, Chelsea College of Arts, London College of Communication, London College of Fashion and Wimbledon College of Arts. UAL was recently ranked one of the world’s top 5 universities for art and design 2016/17 in QS World University Rankings.

Chelsea College of Arts, UAL, is one of the world’s leading art and design institutions specialising in Fine Art, Graphic Design and Interior and Textile Design. Alumni include Turner Prize winning artists Anish Kapoor and Chris Ofili, Oscar winner Steve McQueen and actor Alan Rickman. Chelsea is one of the six Colleges of University of the Arts London (UAL).

www.arts.ac.uk/about-ual

Instagram: @unioftheartslondon

Twitter: @UniArtsLondon

Facebook: UniversityoftheArtsLondon

28 Jul 2016

The Smile – London Design Festival

Design: Alison Brooks Architects

Location: Chelsea College of Arts 16 John Islip Street London SW1P 4JU

The American Hardwood Export Council Presents The Smile by Architect Alison Brooks for The London Design Festival

The American Hardwood Export Council has collaborated with Alison Brooks Architects, Arup and the London Design Festival to present a cross-laminated tulipwood structure on the Rootstein Hopkins Parade Ground of the Chelsea College of Arts from 17 September until 12 October.

Brooks has designed The Smile, an urban installation that showcases the structural and spatial potential of cross – laminated hardwood using American tulipwood. The Smile is one of the Festivals Landmark Projects; a timber structure that can be inhabited and explored by the public.

With expertise from top engineering firm Arup, and using construction sized panels of hardwood CLT for the first time, Alison Brooks’ concept is a spectacular 3.5m high, 4.5m wide and 34m long curved rectangular tube – the first ever hardwood mega-tube.

Alison Brooks says, The Smile is a huge curved hollow tube made of cross-laminated tulipwood. It touches the ground at one point, like a wheel. Entering The Smile through an opening where the curved form meets the ground, the visitor can walk from end to end of the 34-metre-long tube to discover a new kind of space that gradually rises toward light. All four sides of The Smile’s interior will be made of same beautiful hardwood panels as the structure. It will offer a complete sensory experience of colour, texture, scent and sound. The Smile’s two open ends will illuminate the funnel-like interior space and act as balconies to the city.

Along the walls, perforations will allow sunlight to draw changing patterns on the floor throughout the day.

The perforations will also give the visitor an understanding of how the structure performs as they’re located in positions where there are fewer structural stresses. At night the interior will be illuminated by linear light strips that trace its dynamic curving floor.

For AHEC, The Smile is one of the most important developments in a decade of research and development into structural timber innovation with Arup, and one that could broaden the use of CLT in the construction industry. Andrew Lawrence, Associate Director, Arup says, “The Smile is the most challenging structure ever constructed in CLT. Every aspect is pushed to the absolute limit. It really shows the potential for hardwoods in construction.”

This creation of a brand-new product and a new use of hardwood will transform the way architects and engineers approach timber construction.

This structure proves that hardwoods have a role to play in the timber construction revolution, says David Venables, European Director of AHEC. All our previous LDF projects – Timber Wave, Out of the Woods, Endless Stair and The Wish List – have been significant projects.

But The Smile, designed by Alison Brooks Architects, is the most significant advance because it will create the first-ever use of industrial-sized panels of hardwood CLT. These panes will be produced by Züblin Timber in Germany, one of the pioneers of this manufacturing process. They believe in the potential of tulipwood CLT as bringing a revolutionary new element to wood construction.

Arup’s engineering team is working to derive the most efficient structural form, using only 60 cubic metres of wood to create a 150 square metre enclosed space. The forces of tension and compression working in the CLT walls will be expressed by perforations in its elevations. ABA has used these to generate patterns of light across The Smile’s interior spaces during the day, it will become an urban lantern at night.

The Landmark Projects are a key part of the Festivals commissioning programme. They are at a scale that gets noticed and are always in major public places reaching a very wide audience, says Ben Evans, the Director of LDF.

The choice of architect is key and Alison Brooks Architects are known for their innovative use of materials. Alongside a strong commitment to ambitious ideas they made an ideal choice for this years Landmark project with AHEC.

LOCATION: Chelsea College of Arts 16 John Islip Street London SW1P 4JU

DATES: 16 September – 12 October

The Smile – London Design Festival images / information received 280716

Alison Brooks Architects on e-architect

6 Aug 2018

MultiPly London Design Festival Flagship Pavilion 2018

image courtesy of architects

MultiPly London Design Festival Flagship Pavilion

Location: Chelsea College of Arts, 16 John Islip Street, London, SW1P 4JU, England, UK

London Building Designs

Contemporary London Architectural Designs

London Architecture Links – chronological list

London Architecture Tours – bespoke UK capital city walks by e-architect

Tate Modern Extension

Design: Herzog & de Meuron Architects

images © Hayes Davidson and Herzog & de Meuron

Tate Modern, London

Design: Herzog & de Meuron Architects

photo © Adrian Welch

London Festival of Architecture

Comments / photos for the The Smile – London Design Festival page welcome

Website: Alison Brooks Architects